OVERHAULING OF TURBOCHARGERS/ENGINES

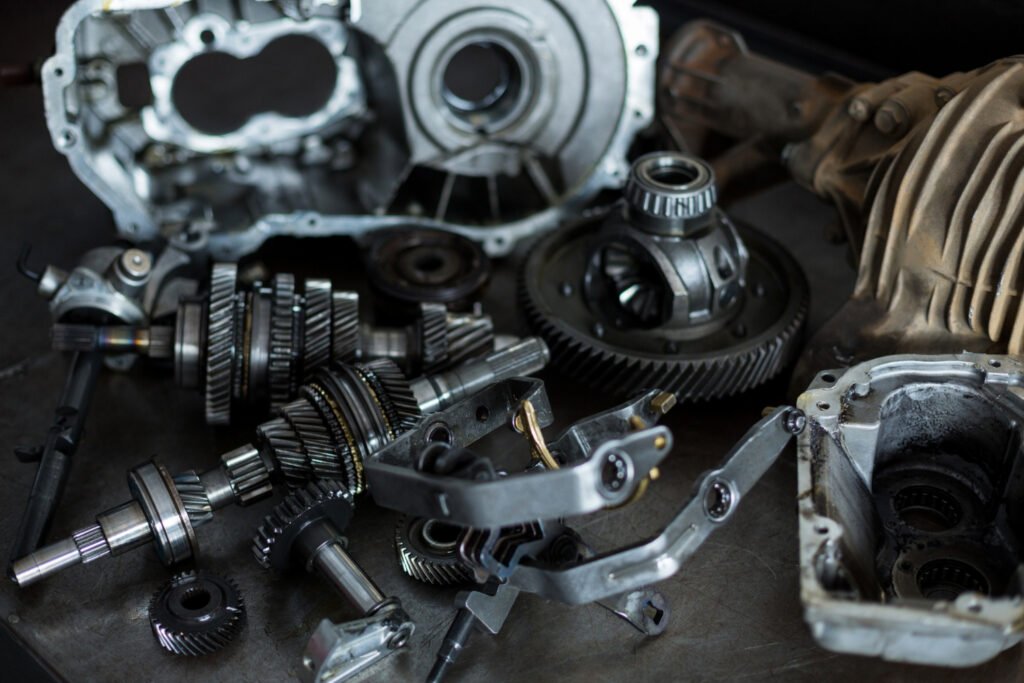

At RAGC GROUP, we offer specialized services in the overhauling and refurbishment of turbochargers and engines, aimed at restoring these critical components to their optimal performance levels. Our comprehensive overhaul process is

designed to extend the service life of turbochargers and engines, enhance efficiency,

and ensure reliability under demanding operational conditions.

1. DISASSEMBLY AND INSPECTION

- Visual & Microscopic Examination: Detailed visual inspections, supplemented by microscopic analysis, to detect cracks, corrosion, and other anomalies.

- Dimensional Analysis: Measurement of critical dimensions such as shaft tolerances, bearing clearances, and component alignments to ensure adherence to manufacturer specifications.

- Performance Diagnostics: Testing of key operational parameters using diagnostic tools to evaluate the performance of components under simulated operating conditions.

2. REPLACEMENT AND REFURBISHMENT

- Component Replacement: Sourcing and installing high-quality, OEM or equivalent components, such as bearings, seals, and turbine blades, to restore the integrity and functionality of the turbocharger or engine

- Refurbishment: Reconditioning parts that are still within acceptable wear limits, including surface grinding, balancing, and precision machining to bring components back to their original specifications.

- Assembly: Reassembling the turbocharger or engine with exacting standards, ensuring all tolerances are met and that components are properly aligned and secured.

3. TESTING AND CALIBRATION

We uphold stringent quality assurance practices to ensure the reliability and

longevity of overhauled components:

- Functional Testing: Operating the turbocharger or engine under controlled conditions to assess performance metrics such as boost pressure, temperature stability, and efficiency.

- Dynamic Balancing: Balancing rotating components to minimize vibrations and ensure smooth operation, thereby extending the life of the turbocharger or engine.

- Calibration: Fine-tuning parameters to optimize performance and fuel efficiency, ensuring compliance with emissions standards and operational specifications.

4. QUALITY ASSURANCE &

DOCUMENTATION

We uphold stringent quality assurance practices to ensure the reliability and longevity of overhauled

components:

- Quality Control Checks: Implementation of multiple quality control stages throughout the overhaul process to ensure adherence to industry standards and client requirements.

- Documentation: Providing detailed reports and documentation of inspection findings, replacement parts, and testing results for transparency and future reference.